Best practice in Industry 4.0: Learnings from LCR4.0. Interview with Simon Reid by Ceri Batchelder, Ad Hoc URBACT expert

Back in 2018, I was working on a project to try and bring together the digital and manufacturing communities in my region to collaborate. I’d heard that the city of Liverpool in the North West of the UK was making big strides in the area of Industry 4.0 and wanted to find out more. Along with a colleague, I was introduced to Simon Reid, then Head of Advanced Manufacturing, who was leading on an ERDF (European Regional Development Fund) funded project called LCR4.0 (Liverpool City Region 4.0).

01. Getting introduced to LCR 4.0

In November 2018, we met with Simon on a stand at Smart Factory Expo, part of the LCR4.0 flagship event, Digital Manufacturing Week. Simon explained that he’d been interested in the potential of digital technologies for the regional business base and commissioned the ‘Making It’ report from the Institute of Manufacturing at the University of Cambridge in 2013.

They identified globally competitive competencies in the Liverpool City Region region, including intelligent systems and big data analysis, which were largely linked to the highly productive automotive and pharmaceutical industries. However, what they also discovered was the low levels of automation amongst the SME (small and medium enterprise) base, especially within the food and drink and chemical sectors.

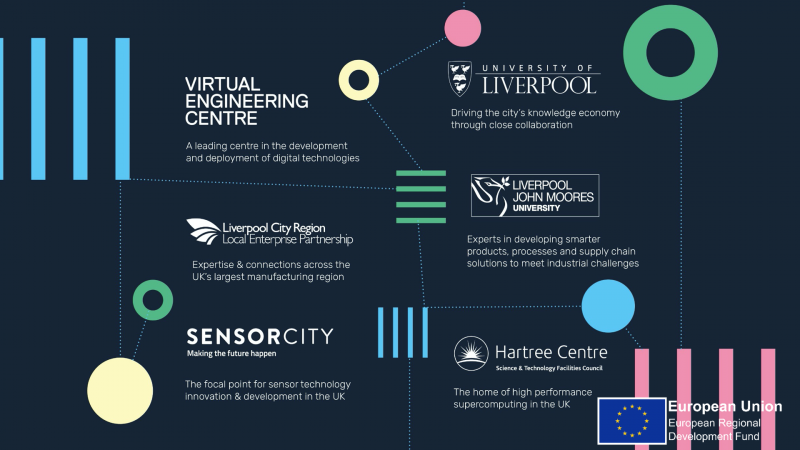

So, LCR 4.0 was born to explore how to help manufacturing SMEs to digitalise - funded via ERDF. The partners developed a joint venture delivery group with both Liverpool’s universities, The University of Liverpool and Liverpool John Moores University, Liverpool City Region Local Enterprise Partnership, Sensor City, the Virtual Engineering Centre and the Hartree Centre (see partners graphic below for detail). This collaborative approach proved successful and following its launch in 2016, the LCR4.0 programme actively engaged over 170 companies to create an industrial digital technology (IDT) ecosystem.

Simon was very open about what worked and what didn’t - he wanted to share the learnings. One of the things he would change is how they initially approached the manufacturing businesses. At first, he and the team would lead on the digital manufacturing technology and the benefits and productivity improvements it could bring, but the manufacturers didn’t respond. Instead, they made appointments to have more detailed discussions, in which they talked about the business and its challenges, and the potential earning and process efficiency gains.

In this way, Simon and his team gained greater traction and started to see companies come together that wouldn’t normally have interacted, such as traditional engineering companies reaching out to IDT suppliers. They also began to see digital manufacturing advocates come forward, who supported them on regional bootcamp events focused on process efficiency, spreading the word through peer to peer learning.

The groundwork laid by LCR4.0 led to the North West region of the UK being selected for the first national Made Smarter pilot, part of the UK’s industrial digitalisation strategy. Designed to support SMEs struggling to adopt digital technology, the pilot provided 50% match-funding (via vouchers) to manufacturers towards carrying out a technology implementation project with an IDT solutions provider (private supplier, university or technology intermediary).

02. Introducing LCR4.0 to AS TRANSFER

Fast forward to January 2022. Since our four AS TRANSFER cities want to understand how best to encourage Industry 4.0 adoption, I knew Simon was the perfect person to deliver the Keynote talk at our network meeting on partnership brokering. Simon presented the LCR4.0 story and 'what happened next' since we met in 2018. We took the opportunity to have a fireside chat with him to ask some of our burning questions!

Ceri: How did you achieve buy-in for the original plans?

Simon: We informed ourselves about Industry 4.0 because we knew that the Liverpool City Region would be left behind if we didn’t embrace it. Through having done the research, we were able to win the hearts and minds of politicians. More challenging was to convince some of the government officials - we needed to explain that Industry 4.0 was coming whether they liked it or not. The larger companies in the City Region were receptive to our Industry 4.0 message, but the SMEs were more hesitant, even though we were trying to help them to become more efficient.

Ceri: Do you use Industry 4.0 as a phrase when talking to companies?

Simon: We have stopped talking about it in this way and the UK government is now using the phrase ‘industrial digitalisation’. At first we were evangelists for new technologies, but in doing so, we weren’t sensitive to the challenges faced by SMEs and were inadvertently switching companies off. Now we ask how we can help the business to become more efficient which is received much more openly.

Also, previously we had reached out to people who understood Industry 4.0 in the business, such as the head of engineering, or those who showed an awareness of the potential. However, we learnt that we needed to focus on the business leaders and bring them on the journey. We needed to change our approach and language.

Ceri: It’s been 3 years since we first met, what has happened with LCR4.0?

Simon: LCR4.0 has had a significant impact, some of the highlights are:

- New innovations, through digital adoption and practical digital strategies bringing new products to market. See the LCR 4.0 website for multiple case studies.

- Increased use of Industry 4.0 skills. For example, virtual tools have helped product development in particular, leading to less complex system integrations being required.

- Economic benefit for the City Region. For every £1 of funding, £3.70 was generated, and due to the long term nature of the work, further value generation is expected in the future.

Ceri: What are your tips on partnership brokering?

Simon: To understand who we needed to bring together, the initial joint venture partners drew a spider diagram with the regional skills sets. We wanted to map these skills against the businesses that needed to go on the Industry 4.0 journey. Where did the new technology need to be integrated and who should be involved?

We looked at who we had in our teams to see who could be seconded to the project. There were some technical specialists, but initially we focused on a small team who were deliberately non-technical, that could go into businesses with a more open mind and broker in the relevant discipline. It was a working model that grew organically, with the public sector providing a critical role as a trusted intermediary.

Impact of LCR4.0 / View an infographic on the impact delivered through LCR 4.0 here

Ceri: If a city had access to a 1M Euro ERDF grant to get started, how would you advise them to spend it?

Simon: I’d advise running a leadership programme for manufacturing business leaders, on a cohort basis – helping to address their challenges and taking them on a journey at the same time. So that they are not embarrassed and start to understand the art of the possible with technology integration, and where things are sub-optimal. Large businesses (Original Equipment Manufacturers (OEMs) and Tier 1s, those at the head of the supply chain) are where the threat will come, as they will expect smaller businesses to be able to digitally integrate with their systems.

Ceri: What about help for the larger firms, what are they doing?

Simon: I’ve done lots of tours of the larger businesses. In some, the level of digitalisation (e.g. robotics) is unbelievable, but surprisingly there is no data integration internally or with suppliers. Others have some digitalisation, but not as much as you’d expect and are paying a lot to consultants to produce their digital strategies.

LCR4.0 was restricted to supporting only SMEs due to the funding criteria. As mentioned, as the large businesses digitalise, they will want to increasingly integrate digitally with their supply chain. They cannot afford the time or risk with SMEs that are not prepared. My job is to digitally enable the supply chain. An inventory of SMEs and their level of digitisation starts to become important. They need to provide larger companies with assurance. We’re thinking about creating a Digital Sandpit, where SME companies can do integration practice.

Ceri: What's next for LCR4.0?

Simon: When the first phase of LCR4.0 came to an end, the learnings fed into successful applications for two further ERDF funded programmes:

Ceri: Lastly, what else do you advise our cities to look out for in their Industry 4.0 journeys?

Simon: SMEs are often quoted large amounts of money for digital interventions, when something simple, such as a software plugin, could be all that’s really needed. It spreads the misconception that Industry 4.0 is expensive.

The more efficient companies become, the greater their level of market opportunity and the better their top line. We focused on product enhancement, which ultimately leads to an increase in cash flow and dividends to shareholders. Whilst this is great for the business, it doesn’t necessarily benefit the region and grow the local economy. So a key aspect is to encourage the businesses to gain market share, which should lead to a scaling in operations, and subsequent increases in jobs and business rates etc, which has wider economic impact.

Finally, don’t forget to communicate and be visible - be public about your Industry 4.0 work. Hold events and roundtables, publish newsletters and case studies. Use communications “to keep the pedal to the metal”.

In Conclusion

Thank you to Simon and his team for being so generous with their time and sharing their learnings. Simon said the biggest pleasure from his work comes from starting to work with an SME that is resistant to the Industry 4.0 message, building the relationship and seeing them change. I think we can all take some valuable tips from the LCR4.0 journey and apply them to our own cities to see our Industry 4.0 initiatives flourish.

Ceri Batchelder and Alison Partridge, URBACT Ad Hoc Experts for AS TRANSFER

January 2022