Circular economy in the built environment, approached from different perspectives: academic, design, architectural, construction, civic and the role of infrastructure for materials’ storage, Destination circular: The case of Copenhagen.

By Dr. Eleni Feleki, Lead Expert of the URGE Action Planning Network

Introduction

Circular economy requires entire systems to be designed depending upon numerous stakeholders (Pedersen and Clausen, 2019). This calls for active collaboration between all the stakeholders in the circular supply chain (Leising et al., 2018). Several studies have indicated that the limited willingness to collaborate within the value chain is one of the barriers (Kirchherr et al., 2018), turning the transition to a circular environment into a difficult task. Stakeholders, acting at different stages within the cycle, will need to establish new ways of working, to seek for new business partners, to assign new roles, and accomplish new kinds of collaborations (Aminoff et al., 2016). Therefore, the success of construction projects that focus on circularity relies to a great extent on establishing efficient collaborative networks within the value chain that facilitate closing of resource loops. The role of researchers, acting closely with designers, architects and constructors in facilitating collaboration is crucial. This collaboration needs to be maintained and enhanced during and after the lifecycle of products, components, buildings and materials. As to close the loop, research, design, construction that address the end of use cycles and end-of-life scenarios become even more important. To date, there is little knowledge concerning how different perspectives can help boost circularity. This thematic article touches the issue of circularity in construction projects, from different perspectives and enhances the importance of collaboration among everyone involved.

Circularity assessment and architectural design: The academic perspective

Which buildings have the opportunity to contribute with the largest increase in value? Which buildings are closest to providing ideal results, if treated within the circular economy approach? How can we adapt our transformation strategies and urban development based on the potentials of the buildings?

Answers are attempted through academic research conducted in the frame of the ‘’Circular Construction In Regenerative Cities’’ project (CIRCuIT), funded by Horizon 2020 programme. Answers are achieved through mapping of transformable neighbourhoods and buildings. Seven distinctive approaches have been identified in the Copenhagen case:

- analyses of building stock patterns

- analyses with planning data and/or urban indicators

- qualitative analysis based on stakeholder discussions

- multi-method approaches, multi-criteria decision-making

- models, identifying ‘natural’ adaptive reuse potential

- calculating transformation capacity indicator

Data availability is a major driver for the selection of a method in practice.

Multi-criteria decision making model

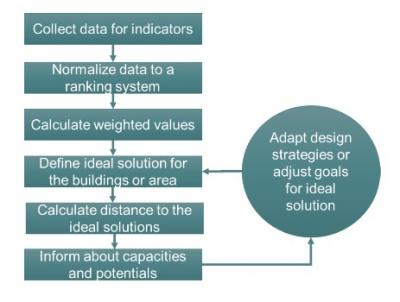

The idea behind MCDM (Multi Criteria Decision Making) is to weigh criteria and their sets of indicators in relation to a predefined ideal situation.

Buildings and urban areas are complex systems. The actual relation between the technical state of the building (for instance assessed via technical due diligence) and the social behaviours of the users is worthy investigating.

MCDM is one of the methods for assessing and visualising improvement potentials for buildings and urban areas taking into account sustainability criteria and performance indicators. Performance indicators are already relatively common in the construction industry and are used to evaluate and provide insights about a variety of different aspects. Examples of indicators used for buildings are energy labels that place them on an energy scale, provided that a series of technical data is available. This makes it easy to visualise the performance of a building in terms of energy balance in relation to the best label value (ideal situation). In principle, MCDM models work like that, measuring the distance to an ideal situation, which in this case is the energy label with the lowest energy consumption. More advanced MCDM must be able to handle many different indicators and be able to weight them as well.

To date, there is a large increase in the prevalence of advanced MCDMs, which are used for sustainability certification of buildings. However, these sustainability certification systems are more developed as an evaluation tool rather than a planning/ decision-making tool for potentials in the planning phase. There is a need for new MCDM models that can be used to evaluate transformations and renovation potentials for existing buildings and urban areas in the early planning phases. In order for this to be possible,

Figure 1: MCDM to adopt design strategies or to adjust goals for ideal solution (source: CIRCuIT project)

it is necessary to identify an ideal situation, and indicate which indicators are important in order to be able to evaluate the potential for transformation of both buildings and in an urban environment, as well as how these indicators should be weighed against each other. A realistic approach is to look at which data is available and choose indicators accordingly taking also into consideration the cost and labour needed for their calculation.

Once the most important indicators have been identified, data must be aggregated, normalized and weighed, so that the performance is assessed. The idea is that the MCDM model will then calculate the distance of the existing system to the ideal solution. If the distance to the ideal solution is important, it is necessary to make many changes to approach the desired ideal solution and answer the questions posed before

Application

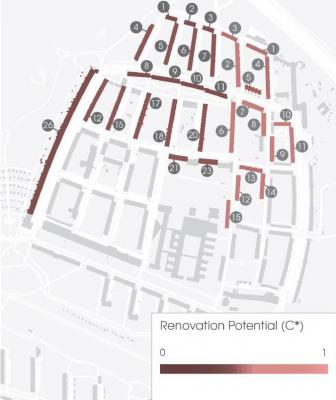

A real case scenario of a MCDM case study has been carried out in the Tingbjerg suburb in Copenhagen, in the frame of the CIRCuIT project and showed how MCDM model can be used to assess and visualise the renovation potential of the buildings located in this area, by evaluating the individual building indicators together with indicators for the urban environment. Results are visualised in Figure 2. Colours depict the renovation potentials. The renovation potential is visualised as the distance from the ideal situation, where the ideal solution has the value of 1. The buildings with dark red colours are therefore the ones farthest away from the ideal solution. These are the buildings that will give most environmental, social, and economic value in case of renovation or replacement. Buildings with the lighter red colours are closest to the ideal situation and are therefore already either in good condition or contribute already through minor improvements.

Figure 2: A real case scenario of a MCDM case study has been carried out in the Tingbjerg suburb in Copenhagen (source: CIRCuIT project)

It still remains to validate the practice through more case studies in different locations in order to identify which building and city level indicators have the greatest impact on the renovation and transformation potential, as well as how they should be weighted and how the ideal situation can be defined. More information here: https://www.circuit-project.eu)

Screening the site: An architectural perspective

Although Denmark, is thinking green, citizens are heavily consuming in relation to other countries. American standards in terms of way of living have introduced a living model that the more you consume, the more successful you are. The approach should change and eliminate the amount of raw materials that are used, by trying to exploit as much as possible secondary materials and design/build with what we have got (material driven design).

Although it might seem easy to take materials and reuse them, this is impossible in some cases, as certified engineers, documentation, certified materials, etc, are needed. All these are ‘’add-ons’’ to the current process, which makes the end-product more expensive. In that case, we need to alter the final goal (i.e. instead of envisioning the building of a high-construction with reused materials, build a lower-construction). Another alternative is to downscale the quality of reused materials, but even then, we need to follow certain standards. Unfortunately, the regulations respond still to a larger extent to the linear economy, which of course flavours the use of raw materials that in most cases are characterised by the same physical parameters, whereas reused materials are different.

Architects play an important role in introducing techniques and showcasing paradigms of constructions that are mostly relying on secondary rather than on raw materials. In Denmark, several projects are already under way, using for example 74% glass from a demolition site, soil from the metro, residue concrete from metro etc. Even in deconstruction phase, architects play a crucial role as they foresee the removal of materials, like glass, in a way that it can be reused in another construction. Reused materials can make their own statement in new constructions, to be make people aware that everything is possible.

Although there are several examples of projects with secondary materials used in Denmark, scaling up is still necessary. It is too expensive to implement the approach in small contracts, as the reality is that standard materials cannot be easily competed. It takes time and effort to persuade the owner to dare for a circular economy construction.

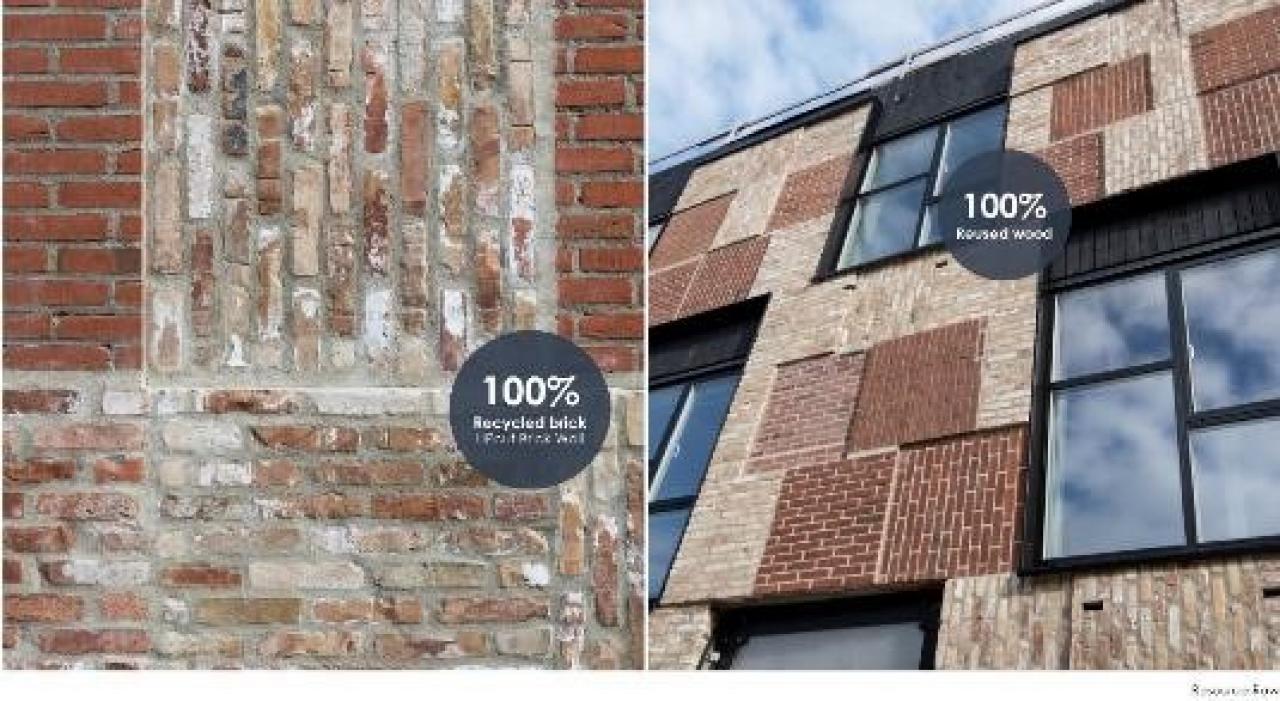

Figure 3: Studios designed and built out of secondary materials in Denmark

Buildings following the circular economy approach cost 8-10% higher than ‘’traditional’’ constructions. However, circular constructions were perceived positively by the byers in Denmark. Currently, new opportunities open for Denmark as the volume of secondary materials that is allowed to be reused in the construction is raising. There is new legislation that allows higher percentage of concrete for example that can be reused.

According to the architectural perspective, another reason to reuse is to ruin this notion that everything needs to be perfect in terms of aesthetic. New ways to design and construct are put forward by architects in Denmark. There are a lot of uses for secondary materials (ie wood and plastic, for conference tables). Some examples are depicted below.

Figure 4: Studios designed and built following circular economy approach in Denmark

Wooden panels

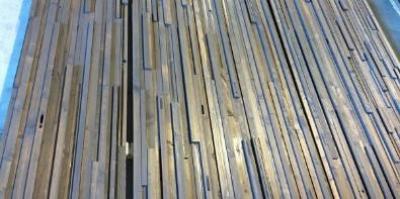

To be able to upcycle wood waste into new products the specific waste fraction must be subjected to several processes and quality assurance tests and analyses.

For the project Copenhagen Towers in Ørestad, in Copenhagen, 60,000 linear metres of wood have been upcycled

Figure 5: Wood panels out of secondary materials

that otherwise would have been wasted. The wood comes from window frames, doors, floors and old scaffolding wood. The wood has been collected by a collaborator who has localised and categorised the material, so that wood can be traced back to its source.

Window frames and doors have been split in such a way that the wood can be planed and cut into regular-sized strips. The strips have then been sent to be fireproofed to be able to comply with the strict fire regulations for indoor cladding. The wood is fireproofed to class B, S1-D0 by using Burnblock, a 100% organic and nontoxic fire retardant.

The wooden stripes are mounted on a back plate in such a way that the wood strips create a varying surface. The mounted wood is then treated with natural paint that is toned with natural pigments. The finished panels are 500mm wide and come in varying lengths of up to 6000mm without any visible seams.

Concrete floor and bricks

Figure 6: Building facade with secondary bricks in Denmark

Pet bottles

Huge amounts of PET bottles are collected, washed, sorted, and granulated, heated and extruded to raw PET fibres. A machine puts layer after layer of PET fibres in the same direction and felts the individual fibres together to form larger felt areas. The very thin PET felt layers are then pressed onto each other in thicker layers to create a stable and robust sheet of PET felt, ready for subsequent processing. PET felt is an environmentally friendly material since it consists of 100% recycled bottles. PET felt has a very soft, felt texture with a slightly rough surface.

For the project Copenhagen Towers in Ørestad, Danish architects were asked to raise the sustainability profile of the project by covering the interior surfaces with upcycled materials. Not only should the materials be sustainable, but they should also fit seamlessly into a high-end, exclusive office setting.

Figure 7: Use of PET bottles to raise the sustainability profile in Copenhagen Towers

The background for the development of the acoustic panels and their design was the assignment to create a suspended ceiling made of recyclable materials. It should act as acoustic regulation, have aesthetic qualities and be visibly as well as measurably sustainable. The specially developed acoustic ceiling panels consist of a back plate onto which PET felt is mounted in an optimised geometry with high acoustic performance. The panels display a compressed sine-wave shape.

The PET felt used for the acoustic panels has both sound dampening and sound absorbing properties. The felt can be used for acoustic regulation in office settings, institutions as well as in homes. The felt in itself has strong aesthetic and tactile qualities, and our supplier works to ‘cradle-to-cradle” standards. More information: Lendager Group

Development perspective

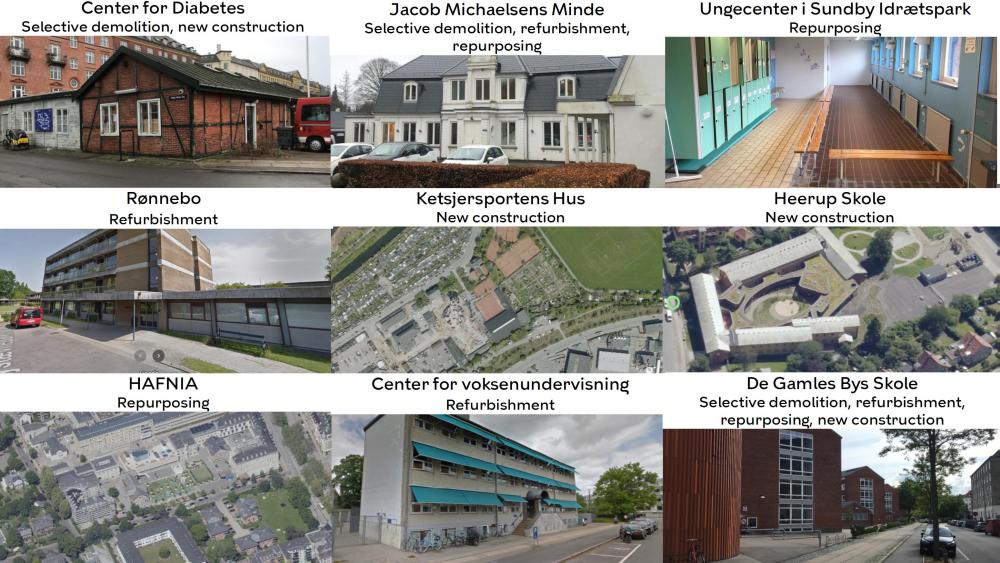

In September 2019, members of the city council in Copenhagen decided that all building projects had to be analysed for the potential of adopting the circular economy approach (following the academic perspective presented above). Currently, there are nine active projects, while four are in the drawing board as well. Seven out of nine projects have received increased financing to work with circular economy. The city has defined 29 principles around circular economy and applies them in the projects. Starting with the definition of priorities, ambitions, goals and strategies, potential actions are targeted and implemented.

Figure 8: Nine projects following circular economy approach in Copenhagen

Figure 9: Principles around circular economy

There is still a list with various products or processes that Copenhagen is exploring to exploit in coming projects:

- Concrete: recycling demolished concrete

- Cross laminated timber (CLT): use of this promising material

- Mineral wool: How is the circularity and how can we substitute?

- Bricks: reuse of bricks, already has a CE mark in Denmark

- Steel: reuse instead of recycling by melting the steel

- Roof tiles: Can we get at CE mark like with the bricks?

The city is closely collaborating with academics, to identify the projects with the biggest potential and apply circular economy practices as well as with architects, to draw their knowledge and expertise and maximise the use of secondary materials.

Closing the loop

None of the above would have been possible if secondary materials were not available.

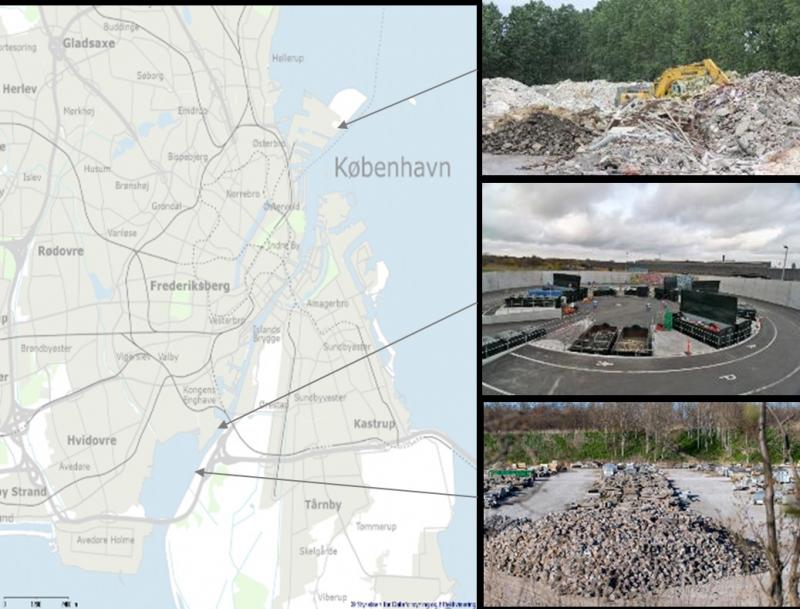

Figure 10: KMC South Harbour, South Harbour Reuse Station and Peterspladsen Municipal Infrastrusture

KMC South Harbour

KMC North Harbour is a material bank: a site for materials (soil) for reuse, only from Municipality works. It is also a treatment facility, where contaminated soil is processed. KMC has operated since 1997 and is 95% owned by the municipality.

In the last 6 years, a lot of new buildings were built, creating the need to dispose soil, so in North Harbour Figure 11: KMC South Harbour

new land is artificially constructed. With the new soil, the harbour has been expanded, new dwellings and recreational areas (30000 people live and work in this new area) were introduced. Revenues from selling that new land financed the city metro. In the next years, a huge island of 2000 m2 will be built, with 80 million tons of disposed soil, where 35000 more people will live and work. Another reason for building the island is to protect the city storm surges through building new islands in combination with dikes.

Moreover, materials are gathered in the area, crunched, and sorted to produce:

- Concrete / Asphalt (0-32 mm) Min 60 % concreate / Max 40 % asphalt Suitable as base layer in road constructions for heavy traffic

- Asphalt (0-16 mm)100 % asphalt Suitable as base layer in bicycles path and pavements

- Asphalt (0-8 mm)100 % asphalt Suitable right beneath tiles in pavements

The South Harbour Reuse Station

The South Harbour Reuse Station in Copenhagen acts as a living lab for future reuse stations, where reusable building materials, doors, windows, and everyday consumer goods are sorted for reuse and sold directly to citizens and companies.

The reuse station is equipped with a large storage facility, where reusable items are stored. Some of the items are sold directly at the reuse station's own reuse builders’ merchant while others are stored for bulk sale directly to local companies via local tenders. In addition, the reuse station acts as an incubator for new circular economy business models. Local entrepreneurs and innovators work at the reuse station's own workshop to develop new products based on the incoming materials. More information, available in the reuse station's website (only in Danish).

Which is the role of active citizens? The Circular Courtyard Programme

A co-creative innovation process has been put forward in Copenhagen, in cooperation with citizens. The innovative process was focused on the recycling of rainwater, as a resource and circular economy, aiming to reduce climate footprint and enhance liveability.

Figure 12: Co-creative innovation process in Copenhagen

The project deals with the design of a courtyard in a building complex located in South Harbour. Solid coatings, sheds and furniture have been cleared to ensure the climate and cloudburst-proof farm and to create a new context and openness in the courtyard. In the design phase, the extent to which playground equipment and old materials from sheds and coatings can be recycled has been assessed. Most of the farm’s self-sown and shrub-like trees have been felled to make room for the farm’s edge and rainwater management.

The smaller trees and shrubs that were worthy of conservation have been excavated and deposited for replanting in the new patio. The climate edge has been produced by recycled concrete, which was mixed with sand-blasted bricks, glass or similar to produce a living surface. Recycled wood has been used for terraces, facade cladding, sheds, and benches. The patio was designed and built using recycled building materials. Fields of recycled tiles have been laid on the footpaths and in the greenhouse as an aesthetic and natural coating. The greenhouse was primarily carried out with recycled windows. A rainwater lake with biological purification where children and adults can play with the water was constructed. The technical rainwater system in the courtyard was built by HOFOR (Copenhagen Utility Company). The whole construction site was fossil- and emission- free.

Through the innovation and involvement process, the residents received help in identifying exactly the parameters that they thought would create the good backyard garden for them. The innovation process also had another important function, which was to open the residents’ horizons for innovative initiatives and ambitious solutions, which they would not have thought of or been interested in.

When the thoughts of circular economy and recycling were brought forward, the residents were therefore ready to think differently, and the implementation of this approach gave them even more ownership of the project, as it became more meaningful not only within their own yard, but also did a difference in a larger perspective.

The different techniques that were used to involve the residents are summarized below:

- Interviewing the residents

- Start- up event

- Innovation workshop with residents

- Innovation workshop with professional partners

- 3 sketch and project development workshop

- Residents' meeting with presentation of the project proposal

- Consultation and support study

- Ongoing dialogue and sparring with the yard- group

- Final celebration with the Mayor

The management model for leading such kinds of projects, with the linear management approach losing ground, is the meta-governance integrated approach, where the middle governor needs to reassure that communication with citizens is well defined, but more importantly, to handle relations (not posing direct control on them) and the dynamics between the different actors. The meta-governor acts like a mediator of processes. In order to make this model work, trust is needed to be built in prior. Also, this model ensures that knowledge is shared between different actors, it empowers citizens and produces sustainable results over time.

In order to establish the climate edge, approximately 500 tonnes of recycled concrete made of crushed concrete from the yard is used. Compared to new concrete, this results in an estimated CO2 saving of 7.4 tonnes.

The project team was composed by the City of Copenhagen, architects, engineering and construction company, property owners and citizens. Especially the citizens, who are members of the owners associations, were an essential stakeholder group for this project to succeed.

Material Depeche: The Bornholm case

A small island occupying an area of 588.36 km2 with a total population of 39,439, occupying an area of 588.36 km2,  turns off the incinerator in 2032 and will treat all waste as a resource. Everything that the locals and the tourists call waste today, will be used again, or have a new life in other products. The waste vision is part of Bornholm’s overall green strategy “Bright Green Island”.

turns off the incinerator in 2032 and will treat all waste as a resource. Everything that the locals and the tourists call waste today, will be used again, or have a new life in other products. The waste vision is part of Bornholm’s overall green strategy “Bright Green Island”.

In approximately 13 years, in the year 2032, a new green reality awaits in Bornholm. The waste system, as known today, with containers for combustible waste and waste incineration in large furnaces, will be gone. Waste such as cotton swabs, armchairs and carpets will no longer be thrown into the incinerator, but instead, have new life as recycling, or become part of another product. Better sorting will be implemented, new and smarter technological treatments will be installed and dialogue with the users, both locals and the thousands of tourists who visit the island every year, will be put forward.

According to Jens Hjul-Nielsen, manager at BOFA, Bornholm’s municipal waste management company, this island is an obvious place to develop competences in green transition and circular economy. The island has a fully developed infrastructure and a population that corresponds to approximately one per cent of the Danish population. Experience and knowledge can, therefore, be transferred to similar projects in Denmark and other places in the world (https://bornholm.info/en/bornholm-shows-the-way/). More information about Bornholm’s ambitious waste vision is available here.

Acknowledgments

This article has been produced in the frame of the URGE APN, financed by the URBACT Programme.

All partners have contributed with input in the frame of the transnational exchange meeting, hosted digitally by the City of Copenhagen, Denmark that is one of the partners in the URGE project, led by the City of Utrecht.

Special thanks to the team and actors from Copenhagen, for their valuable contributions, presentations and insights, namely: Øystein Leonardsen, Green Transition Coordinator, City of Copenhagen, Jens Runge, Managing Consultant in Circular Construction, City of Copenhagen, Frederik Lund Nielsen, URGE ULG coordinator, City of Copenhagen, Ann Birgitte Sørensen, Environmental Planner, City of Copenhagen, Christian Wittrup, Head of Commercial, Lendager Up, Rune Andersen, PhD-student in circular construction, Technical University of Denmark, Rocio Paniagua Jensen, Project Manager, Regional Municipality of Bornholm.

Resources

- How to identify buildings for life-cycle extension? Guide for case selection via the mapping of transformable neighbourhoods and buildings. CIRCuIT project, Horizon programme;

- Vision for waste and resource management on Bornholm (BOFA)

- Procurements in public constructions (Klimate KIC)

- S. Pedersen, C. Clausen, Staging Co-Design for a Circular Economy, in: Proceedings of the Design Society: International Conference on Engineering Design, Cambridge University Press (2019), pp. 3371-3380, 10.1017/dsi.2019.344

- E. Leising, J. Quist, N. Bocken, Circular Economy in the building sector: Three cases and a collaboration tool, Journal of Cleaner Production, 176 (2018), pp. 976-989, 10.1016/j.jclepro.2017.12.010

- Kirchherr, J., Reike, D., Hekkert, M., 2017. Conceptualizing the circular economy: An analysis of 114 definitions. Resources, Conservation and Recycling 127, 221–232. 10.1016/j.resconrec.2017.09.005

- A. Aminoff, K. Valkokari, O. Kettunen, Mapping multidimensional value(s) for co-creation networks in a circular economy, IFIP Advances in Information and Communication Technology (2016), 10.1007/978-3-319-45390-3_54